Syspro’s Material Requirements Planning platform helps manufacturers and distributors accelerate production while reducing costs. Our purpose-built MRP software creates realistic schedules, optimizes inventory levels, and ensures materials arrive precisely when needed.

This intelligent, date-driven system delivers real-time supply chain visibility that enables you to serve your customers faster and more reliably.

Because of Syspro’s intelligent demand forecasting and material planning software, you eliminate excess inventory across multiple locations while ensuring materials are available when your customers need them.

Accelerate production cycles while reducing working capital requirements through precise material timing that enables you to deliver value to your customers faster.

Consistently meet delivery promises with realistic production schedules and accurate available-to-promise calculations powered by advanced production scheduling software that boost order fulfillment.

Proactively identify critical resource bottlenecks and overloaded work centers to prevent production delays and optimize resource utilization.

Gain real-time visibility across your entire supply chain from raw materials to finished products, enabling better supplier performance and risk management.

Perform unlimited “what-if” scenarios using snapshot technology to evaluate planning changes without impacting live operations. This ensures you make the best business decisions.

Bucket-less Date-Driven Planning

Our advanced MRP software planning engine schedules by specific dates instead of time periods, delivering the precision and flexibility your complex manufacturing operations demand.

Master Production Schedule Management

Create and manage detailed production schedules for finished products and spare parts, with real-time build schedule generation and online MPS review capabilities

Dynamic Capacity Planning

Assess work center loads, perform load leveling, and use forward finite scheduling to resolve capacity constraints within manufacturing time frames.

Comprehensive Demand Management

Calculate demand from multiple sources including sales orders, forecasts, safety stock, and supply chain transfers with user-defined gross requirement rules.

What-If Scenario Analysis

Execute unlimited what-if analyses using live data snapshots without disrupting operations, then convert approved plans to transactions with complete visibility and control.

Intelligent Action Management

Produce actionable recommendations for purchase orders, work orders, and supply transfers. It includes detailed tracing information to connect requirements to their sources.

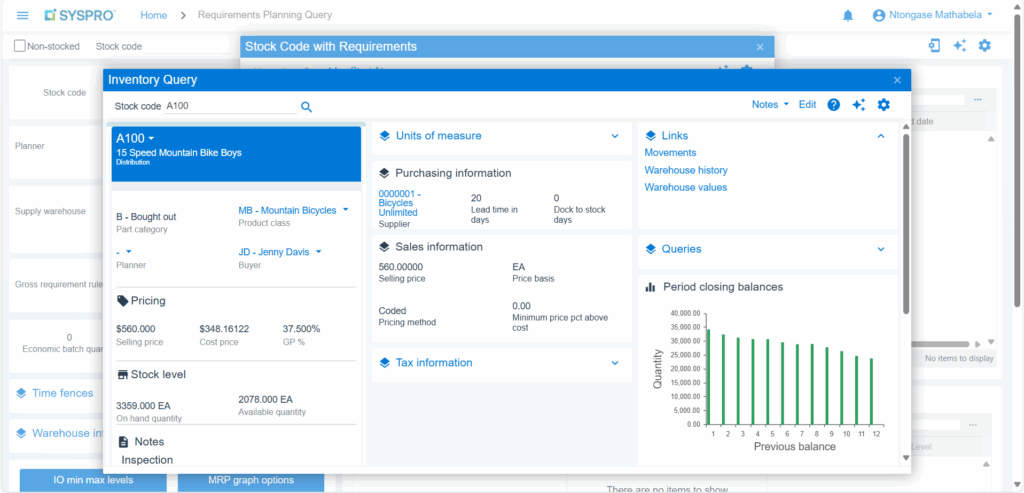

Provides the foundation for balancing supply and demand, managing stock policies, safety stock levels, and gross requirements rules across all warehouse locations with integrated material planning software capabilities.

Determines component requirements for manufacturing parent parts and calculates accurate manufacturing lead times for multi-level production planning.

Acts as primary demand source, feeding customer requirements into MRP calculations while enabling available-to-promise calculations for realistic delivery commitments.

Functions as supply source and receives suggested purchase order recommendations, enabling automatic conversion of planning suggestions into procurement actions.

Integrates job scheduling and material allocations for capacity requirement calculations, ensuring production plans align with available manufacturing resources through production scheduling software integration.

Provides confirmed demand forecasts as approved input for Requirements Planning, enhancing demand accuracy through statistical forecasting methods.

Incorporates customer quotes with specified probability into demand calculations, enabling more comprehensive planning that includes likely future orders.