Built-in Visibility with Lot Traceability Software and Product Traceability Software That Protects Your Customers and Your Brand

Because of Syspro’s purpose-built lot traceability software platform, manufacturers and distributors gain complete visibility and control over their operations. This intelligent product traceability software solution transforms how you manage quality by delivering instant insights into product history, faster response to quality issues, and the operational confidence to make smarter decisions.

From raw material receipt to customer delivery, track every component with precision while keeping your operations running efficiently and your customers protected.

Because of Syspro, you gain intelligent visibility from raw materials to finished products. Instantly identify which components went into specific products, enabling faster decision-making and more efficient operations.

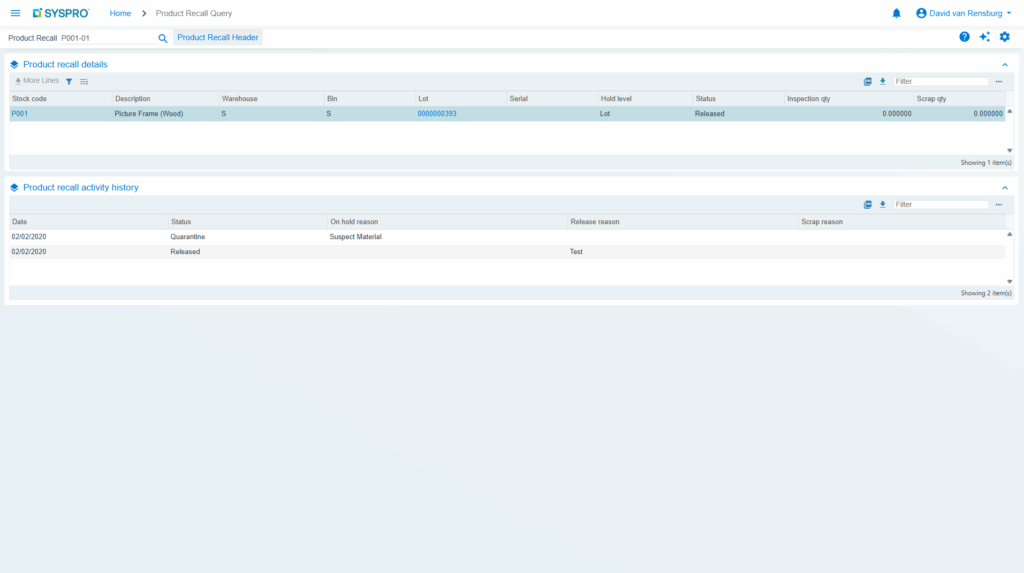

Because of Syspro‘s intelligent traceability, you respond to quality issues in minutes, not hours. Rapidly identify affected products and customers, protecting both your reputation and your customers’ safety.

Because of Syspro’s purpose-built batch tracking ERP approach, you confidently support FDA, HACCP, and ISO 9001 requirements. Establish automated traceability policies that transform compliance from a burden into a competitive advantage.

Because of Syspro, you stay ahead of quality issues before they impact customers. Automatically track expiry dates and quarantine questionable stock, turning quality control into a competitive advantage.

Because of Syspro, you demonstrate unwavering commitment to customer safety. Build lasting relationships through transparent quality practices that protect both your customers and your brand reputation.

Because of Syspro‘s proactive approach, you avoid the devastating costs of major recalls. Transform potential billion-dollar liabilities into manageable quality improvements that strengthen your operations.

Bi-Directional Traceability

Perform both forward (raw materials to customer) and backward (customer to raw materials) traceability queries to quickly identify affected products and source components during quality investigations.

Component-to-Parent Tracking

Link component lot and serial numbers to parent products, enabling comprehensive tracking from individual components through assembly to final finished goods.

Automated Lot Number Management

Configure automatic or manual lot number assignment, with options for lot numbers to equal job numbers, and support for both numeric and alphanumeric numbering systems.

Automatic Lot Depletion

Configure automatic depletion of lots based on expiry dates using FEFO (First Expired, First Out) methodology, ensuring optimal inventory rotation and minimizing waste from expired products.

Flexible Date Tracking

Log up to five user-defined dates for each lot, like manufactured date, best before date, and expiry dates. Automatic depletion occurs based on expiry date order.

Essential integration where stock codes are flagged as lot traceable, providing the foundation for all traceability functions and enabling complete inventory visibility across warehouses and bins.

Records lot numbers during job creation, material issuance, and finished goods receipting with batch tracking ERP capabilities, enabling component-to-parent tracking and supporting reserved lot allocation for manufacturing jobs.

Captures lot numbers during purchase order entry and receipt/inspection processes, maintaining traceability links from supplier documentation through to internal inventory records.

Enables lot allocation during order entry and shipment, ensuring customers receive tracked products while maintaining complete records for potential recall scenarios.

Integrates with inspection processes to record quality data against specific lots, supporting compliance requirements and enabling quality-based hold and release decisions.

Processes returned items with lot number tracking, enabling analysis of quality issues and supporting root cause analysis for defective products.

Incorporates expiry dates into planning calculations, ensuring lot-tracked materials are consumed within quality parameters and supporting FEFO (First Expired, First Out) strategies.