The Bill of Materials (BOM) is essential for your manufacturing process. It helps you track expected costs against actual costs. Our bill of materials ERP serves as a single source for planning materials and capacity, managing shop floor operations, and calculating costs across engineering, production, and purchasing.

By having a complete overview of all components and operations through our product structure management solution, you can create accurate quotes, improve inventory management, and produce goods more efficiently. This ensures you have full visibility and control over your end products.

Minimize material waste and control production costs through accurate scrap tracking, what-if costing simulations, and cost implosion analysis that provides visibility into true production costs before implementation.

Deliver quality products on time with precise material and capacity planning, automated lead time calculations, and comprehensive shop floor control that optimizes your entire manufacturing process.

Reduce work-in-progress, throughput time, and setup times by optimizing product structures, routing alternatives, and capacity utilization across multiple production lines and locations.

Ensure engineering, production, purchasing, and order processing teams work with consistent, accurate product structure information from a single repository, eliminating costly miscommunications.

Support multiple manufacturing routes for lead time optimization, cost modeling, and contingency planning, allowing greater agility to respond to changing market demands and production challenges.

Maintain precise component specifications and manufacturing operations for consistent production quality and enhanced manufacturing control across all product lines.

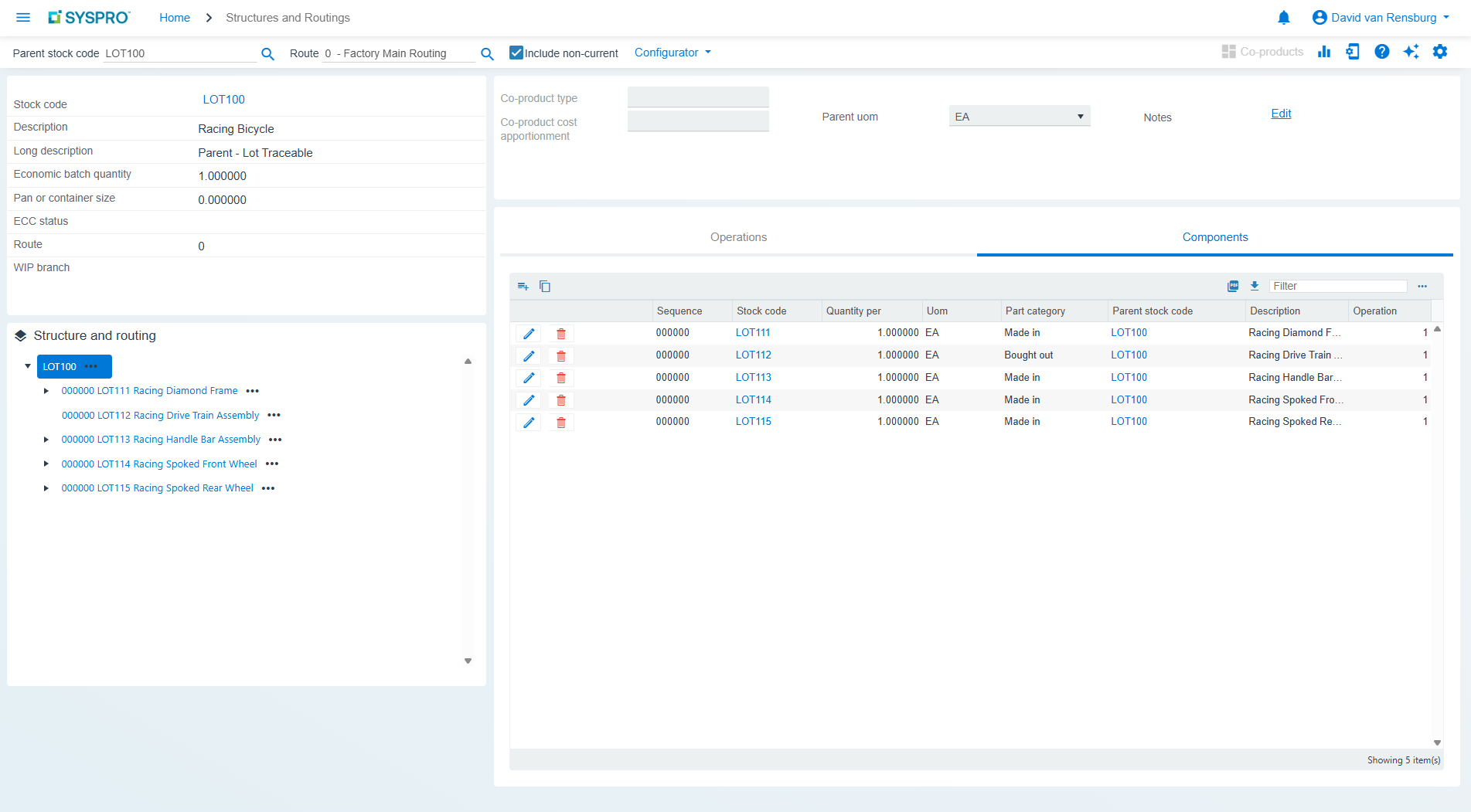

Multi-Level Product Structure Management

Create and manage complex product hierarchies with our multi-level BOM software supporting up to 15 levels of components, sub-assemblies, and raw materials, including diverse BOM types like planning bills, percentage bills, phantom parts, and kit parts.

Costing and Analysis

Utilize what-if costing simulations, cost implosion calculations, and actual costing tracking to analyze material and operation costs from the lowest BOM level upwards, providing complete cost visibility.

Routing and Operations Control

Model complete manufacturing processes with detailed routing sequences, work center assignments, setup times, run times, tooling requirements, and support for alternate routings and subcontract operations.

Lead Time and Capacity Planning

Calculate manufacturing and cumulative lead times automatically while managing capacity calendars for each work center. This supports dynamic elapsed time calculations and capacity unit conversions.

Co-Product and By-Product Management

Handle complex manufacturing scenarios including planned co-products and incidental by-products with robust costing apportionment methods and material availability checking through trial kitting.

Engineering Change Control Integration

Maintain discipline and control over BOM modifications by integrating with Syspro’s Engineering Change Control module. This ensures proper management of the design and release process.

BOM structures are built upon stock codes defined in Inventory Management, with part categories determining BOM configuration. This foundational integration ensures consistent product definitions across all manufacturing processes.

Utilizes BOM structures and routings to generate expected costs, calculate accurate lead times, and automatically allocate components and operations when creating production jobs, streamlining shop floor execution.

Leverages BOM routings to determine precise quantities and due dates for suggested jobs and purchase orders, enabling automated material planning based on customer demand and inventory levels.

Enables accurate overhead cost apportionment across manufacturing operations, providing detailed cost analysis that supports informed pricing decisions and profitability analysis.

Imports work center details, machine specifications, toolset information, and routing data from BOM to create optimized production schedules that maximize capacity utilization and minimize throughput times.

Uses Cost/Lead Time Roll-up functionality to process BOM routings and develop accurate costing and pricing for customer quotes, ensuring profitable quotations based on real manufacturing costs.

Integrates single-level BOMs for kit-type parent products to automatically generate detailed order lines during sales order entry, streamlining order processing for manufactured assemblies.

Enforces disciplined change management over BOM modifications and shop floor routings, ensuring proper approval workflows and maintaining audit trails for product structure changes.